fektheri phepelo moropa mofuta oa motlakase rapameng grinder

Motlakase o otlolohileng o sebelisoa bakeng sa mefuta eohle ea patsi ka katleho e phahameng, hape ho rarolla bothata ba lisebelisoa tse nang le lipekere kapa litšepe li tla kenngoa mochine ka ho toba.

Liphello tsa li-chips tsa patsi li ka fetoha joalo ka tlhoko ea bareki bakeng sa eona e laoloang ke lehlakore le ka hare la sefe.

Ho sa le joalo, mochine o kopanyang oa lehong o kopantsoe le lirolara tsa hydraulic tse ka phahamisoang kapa tsa theoha joalo ka bophahamo ba thepa.ho bonolo haholo ho sebetsa.

thepa e tala ea lehong: lehong, masalla a ho lokisa (makala, batten, log core, litempele tsa moaho, metso, litšila, joalo-joalo) boto ea likaroloana, boto ea fiber.

Lintho tse tala tse se nang lehong: 'moba, lehlaka, bamboo joalo-joalo.

Morero: feme ea boto ea likaroloana, fiberboard e phahameng haholo, feme ea litlhaka, setsi sa matla a biomass, feme ea lehong.

Molemo

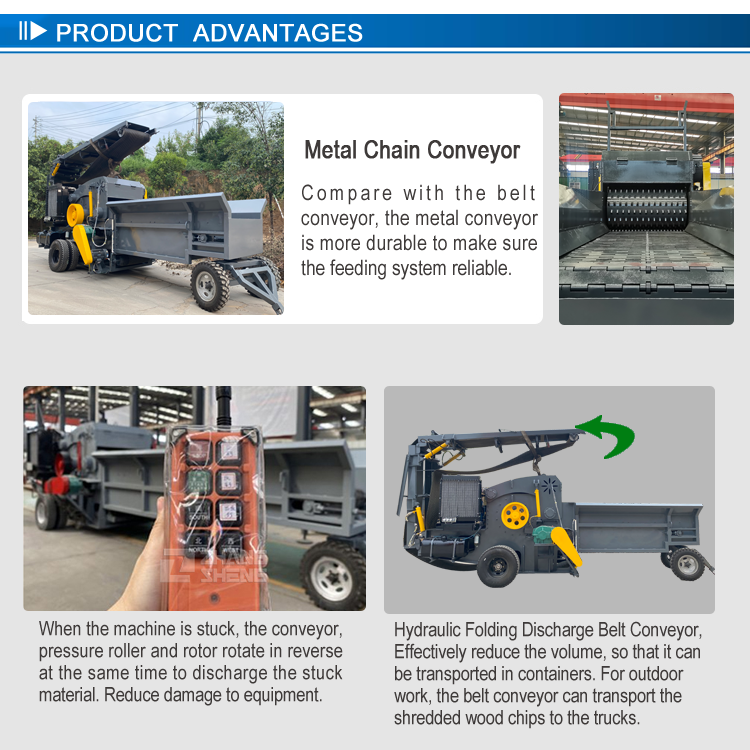

(1) Rotor e ncha ea lehare, li-blade li bonolo ho nkeloa sebaka.

(2) Sekoaelo sa kamore e pshatlehang se ka buloa ka hydraulic, bonolo bakeng sa tlhokomelo le mahare a fetohang.

(3) Boholo ba marang-rang bo etselitsoe litlhoko tse fapaneng ka boholo ba sehlahisoa sa ho qetela.

Sistimi ea buffer ea Hydraulic e netefatsa ts'ebetso e bonolo

(4) Sesebelisoa sa phepelo se khutlisetsang morao, conveyor ea lebanta e ka khutlisoa hantle.Sesebelisoa sena se ka sireletsa mochini, ha ho kopana le patsi e kholo

5

1. Meshing blade e sebelisetsoa ho senya thepa ka ho feletseng;

Lehare le khethehileng le tla khethoa, 'me boima ba lehare bo ke ke ba ba tlase ho HRC55;

2. Sebopeho se matla le lipoleiti tse thata tse ajoang ka bongata li tiisa hore lebokose le matla ebile le tiile;

3. Konopo e iketsang, taolo e hole, e bolokehileng ebile e loketse;

4. Lebanta la conveyor le sesebelisoa sa ho tlosa tšepe li ka ba le lisebelisoa.

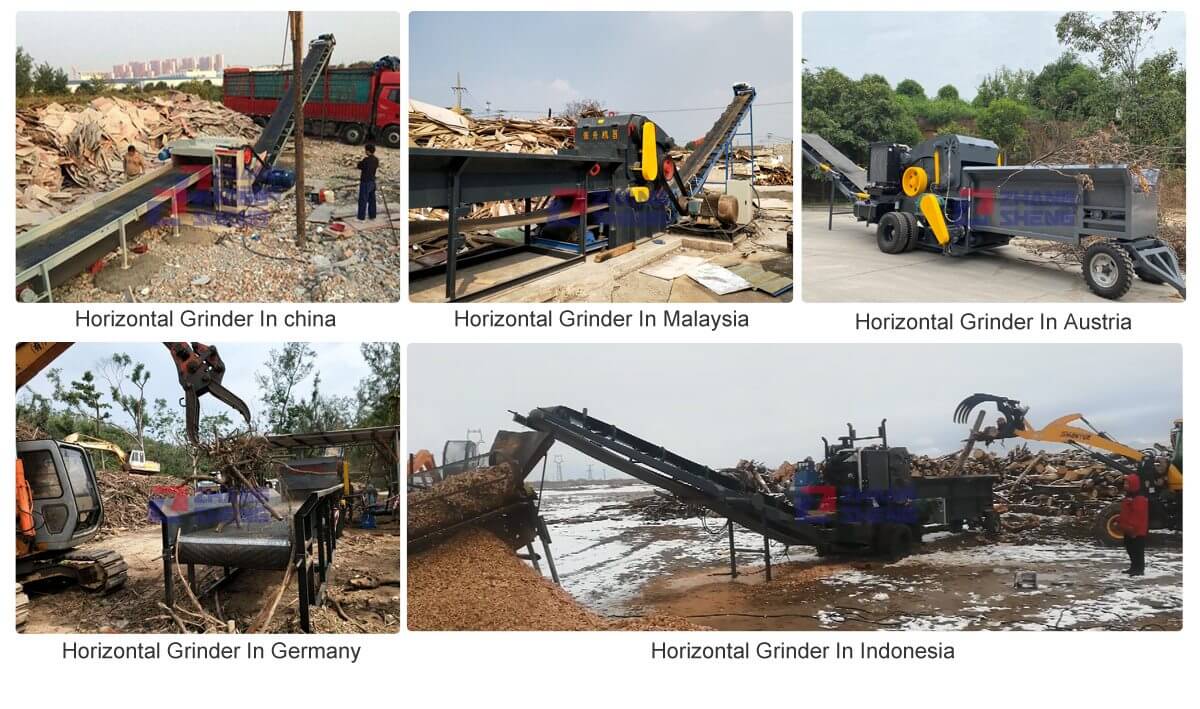

Re nka likarolo tsa theknoloji e tsoetseng pele, moralo le mesebetsi ea matsoho, theknoloji e kopaneng e tsoang USA, Jeremane, Japane le Australia, ha e tšoanele 'maraka oa China feela le meru, hammoho le lisebelisoa le linaha tse fapaneng.

E itšetlehile ka theknoloji e phahameng, litšebeletso tse phahameng ka mor'a ho rekisa le lilemo tse fetang 20 tsa boiteko bo matla, mochine oa rona o fumane botumo bo botle har'a bareki marakeng a malapeng le a mose ho maoatle.Mochini oa Zhangsheng ke morekisi oa hau ea tšepahalang oa mochini.

| Mohlala | Matla a Enjine (hp) | Bophara ba Boema-kepe (mm) | Lebelo la Spindle (r/min) | Matla a Motlakase (kw) | Bokhoni ba tlhahiso (kg/h) |

| ZS800 | 200 | 800×1000 | 900 | 75/90 | 8000-10000 |

| ZS1000 | 260 | 1000×1000 | 800 | 90/110 | 10000-12000 |

| ZS1300 | 320 | 1300×1000 | 800 | 132/160 | 12000-15000 |

| ZS1400 | 400 | 1400×1000 | 800 | 185/200 | 15000-20000 |

| ZS1600 | 500 | 1600×1000 | 800 | 220/250 | 25000-35000 |

| ZS1800 | 700 | 1800×1000 | 800 | 315 | 40000-50000 |

Q1: U amohela mekhoa efe ea ho lefa?

Re ts'ehetsa mekhoa e fapaneng ea ho lefa, re ka amohela 20% kapa 30% joalo ka depositi.

Q2: Nako ea hau ea ho fana ka nako e kae?

Re na le lisekoere-mithara tse fetang 1500 tsa pokello ea lihlahisoa tsa thepa, 'me hangata ho nka matsatsi a 5-10 bakeng sa thepa e nang le lethathamo le lekaneng.Haeba o hloka ho etsa lisebelisoa ka mokhoa o ikhethileng, ho nka matsatsi a 20-30.Re tla etsa sohle se matleng a rona ho fana ka litšebeletso kapele kamoo ho ka khonehang.

Q3: Ho thoe'ng haeba mochine o senyehile?

Tiisetso ea selemo se le seng le ts'ebeletso e felletseng ea kamora thekiso. Kamora nako ena, re tla lefisa litefiso tse tlase ho boloka ts'ebeletso ea kamora thekiso.